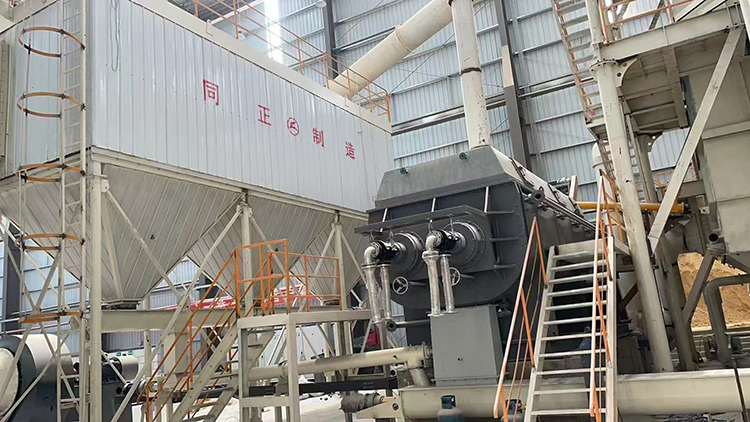

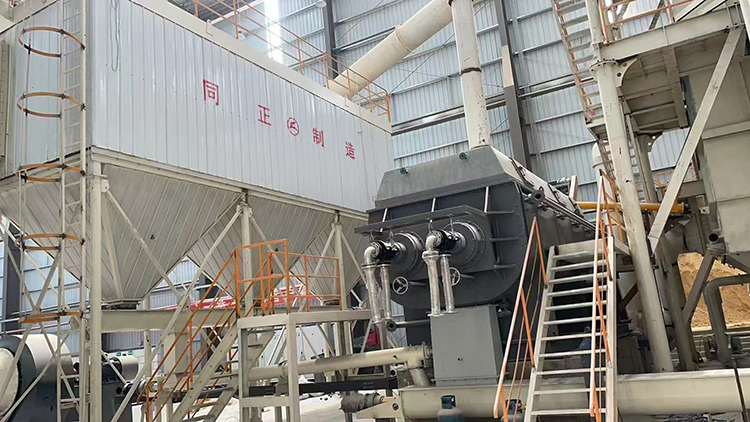

Bag-type Dust Collectors For Cement plants, lumber mills, and sand plants.

The Pulse Jet Baghouse Dust Collector is a highly efficient filtration system designed to remove particulate matter from industrial exhaust gases. Utilizing advanced pulse-jet cleaning technology, this dust collector ensures optimal performance with minimal maintenance, making it ideal for applications in cement production, metalworking, power generation, chemical processing, and other industries requiring high-efficiency air pollution control.

1. High-Efficiency Filtration

– Equipped with durable filter bags (typically made of polyester, PTFE, or other high-temperature materials) that capture fine dust particles, achieving filtration efficiency of 99.9% or higher

2. Pulse-Jet Cleaning Mechanism

– Uses compressed air pulses to dislodge dust accumulated on the filter bags, ensuring continuous operation without frequent downtime. The automated cleaning system enhances bag life and maintains consistent airflow.

3. Robust Construction

– Fabricated from carbon steel, stainless steel, or coated materials for corrosion resistance. Modular designs allow customization for different capacities and operational conditions (e.g., high-temperature or explosive environments).

4. Low Maintenance & Energy Saving

– The pulse-jet system reduces manual cleaning needs, while optimized airflow design minimizes pressure drop, lowering energy consumption.

5. Wide Applications

– Suitable for industries such as:

– Cement & Mining (kiln emissions, crushing dust)

– Metallurgy(furnace fumes, metal grinding)

– Wood Processing (sawdust, sanding particles)

– Pharmaceuticals & Chemicals(powder handling).

6. Optional Features

– Explosion-proof designs (with pressure relief vents).

– Hopper & Rotary Valves for dust discharge automation.

– PLC Control Systemfor real-time monitoring of pressure, temperature, and cleaning cycles.

Bag-type dust collectors Description

Factory Price Industrial Baghouse Smoke Dust Bag Filter for Sand Plant/Cement Factory/Wood Working

Introduction

The Pulse Jet Baghouse Dust Collector** is a highly efficient filtration system designed to remove particulate matter from industrial exhaust gases. Utilizing advanced pulse-jet cleaning technology, this dust collector ensures optimal performance with minimal maintenance, making it ideal for applications in cement production, metalworking, power generation, chemical processing, and other industries requiring high-efficiency air pollution control.

Key Features & Description

1. High-Efficiency Filtration

– Equipped with durable filter bags (typically made of polyester, PTFE, or other high-temperature materials) that capture fine dust particles, achieving filtration efficiency of 99.9% or higher

2. Pulse-Jet Cleaning Mechanism

– Uses compressed air pulses to dislodge dust accumulated on the filter bags, ensuring continuous operation without frequent downtime. The automated cleaning system enhances bag life and maintains consistent airflow.

3. Robust Construction

– Fabricated from carbon steel, stainless steel, or coated materials for corrosion resistance. Modular designs allow customization for different capacities and operational conditions (e.g., high-temperature or explosive environments).

4. Low Maintenance & Energy Saving

– The pulse-jet system reduces manual cleaning needs, while optimized airflow design minimizes pressure drop, lowering energy consumption.

5. Wide Applications

– Suitable for industries such as:

– Cement & Mining (kiln emissions, crushing dust)

– Metallurgy(furnace fumes, metal grinding)

– Wood Processing (sawdust, sanding particles)

– Pharmaceuticals & Chemicals(powder handling).

6. Optional Features

– Explosion-proof designs (with pressure relief vents).

– Hopper & Rotary Valves for dust discharge automation.

– PLC Control Systemfor real-time monitoring of pressure, temperature, and cleaning cycles.

Advantages Over Other Systems

– Higher dust-holding capacity compared to mechanical shakers or reverse-air baghouses.

– Compact footprint with vertical bag arrangement, saving space.

– Adaptability to handle varying dust loads and particle sizes.

| 规格型号 model | TZQM96-4 | |

| 处理风量Air volume(m³/h) | 26800 | |

| 总过滤面积Total filter area(m²) | 372 | |

| 收尘室数(个)Chamber(pcs) | 4 | |

| 每室袋数(条)Quantity of filter bag(pcs) | 96 | |

| 滤袋总数(条)Total quantity of filter bag(pcs) | 384 | |

| 脉冲阀(带电磁阀) Pulse Valve | 数量(个) Quantity(pcS) | 4 |

| 规格(英寸)Specitication(inch) | 3” | |

| 滤袋规格 Specification of filter bag(D*Lmm) | φ130*2450 | |

| 滤袋材质Filter bag material | 根据烟气性质选用Based on flue gas properties | |

| 过滤风速Filtration speed(m/min) | 0.8~2.0(根据不同的工艺选取不同的净化过滤风速)Adjustable | |

| 承受负压Negative pressure(Pa) | ≤6000 | |

| 除尘器阻力Resistance(Pa) | 1470~1770 | |

| 入口气体含尘浓度Inlet dust concentration(g/Nm³) | <1300 | |

| 喷吹压力Blowing pressure(Mpa) | 0.5~0.7 | |

| 压缩空气耗量Compressed air consumption(Nm/min) | 1.2 | |

| 锁风装置Air-locking unit | 根据工艺情况需要确定 Adjustable | |

| 螺旋输送机Screw converyor | 根据工艺情况需要确定 Adjustable | |

| 保温面积Area of heat preservation(m²) | 110 | |

Bag-type dust collectors Applications for cement plants, lumber mills, and sand plants

– Cement & Mining (kiln emissions, crushing dust)

– Metallurgy(furnace fumes, metal grinding)

– Wood Processing (sawdust, sanding particles)

– Pharmaceuticals & Chemicals(powder handling).