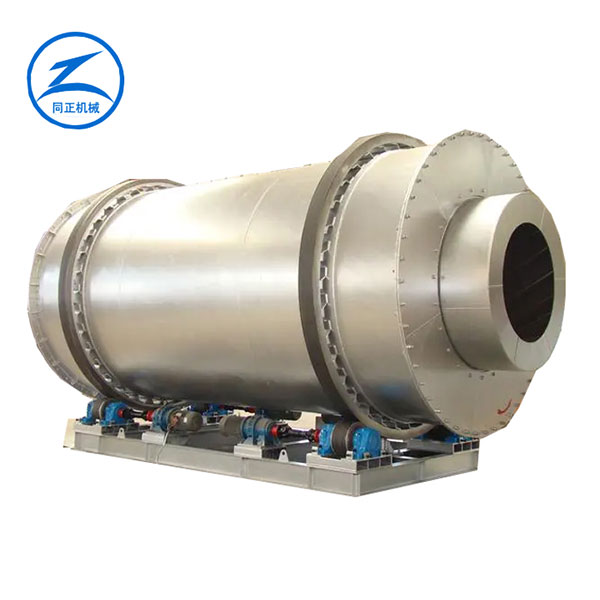

New three-drum rotary dryer for drying silica sand

The Triple-Drum Rotary Dryer is an advanced industrial drying system designed for high-efficiency moisture removal from bulk materials such as sand, slag, clay, minerals, and biomass. Its unique three-cylinder structure enhances heat utilization, reduces energy consumption, and ensures uniform drying.

Key Features

- High Thermal Efficiency

– Three concentric cylinders maximize heat exchange, reducing fuel consumption by 20-30% compared to single-drum dryers.

– Inner and outer drums optimize hot air circulation, minimizing heat loss.

- Compact & Space-Saving

– The nested drum design reduces the machine’s length by 40-50%, making it ideal for limited-space installations.

- Uniform Drying

– Material flows through multiple layers, ensuring even heat distribution and preventing over-drying or clumping.

- Low Maintenance & Robust Construction

– Made from wear-resistant steel with thermal insulation to withstand high temperatures (up to 700°C).

– Reduced dust emissions with optional bag filters or cyclones.

- Wide Material Adaptability

– Suitable for granular, powdery, and high-moisture materials (e.g., sand, coal, sawdust, ore, sludge).

drum rotary dryer

The Triple-Drum Rotary Dryer is an advanced industrial drying system designed for high-efficiency moisture removal from bulk materials such as sand, slag, clay, minerals, and biomass. Its unique three-cylinder structure enhances heat utilization, reduces energy consumption, and ensures uniform drying.

Key Features

1. High Thermal Efficiency

– Three concentric cylinders maximize heat exchange, reducing fuel consumption by 20-30% compared to single-drum dryers.

– Inner and outer drums optimize hot air circulation, minimizing heat loss.

2. Compact & Space-Saving

– The nested drum design reduces the machine’s length by 40-50%, making it ideal for limited-space installations.

3. Uniform Drying

– Material flows through multiple layers, ensuring even heat distribution and preventing over-drying or clumping.

4. Low Maintenance & Robust Construction

– Made from wear-resistant steel with thermal insulation to withstand high temperatures (up to 700°C).

– Reduced dust emissions with optional bag filters or cyclones.

5. Wide Material Adaptability

– Suitable for granular, powdery, and high-moisture materials (e.g., sand, coal, sawdust, ore, sludge).

Technical Specifications

– Capacity: 5–200 t/h (customizable)

– Moisture Reduction: From 30-40% to <1%(adjustable)

– Heat Source: Coal, gas, biomass, or electric heating

– Temperature Range: 150–700°C

– Control System: Manual or automated (PLC-based)

Applications

Construction: Sand, gravel, clay, gypsum

Mining & Metallurgy: Ore, mineral powder, slag

Agriculture: Biomass, wood chips, feed

Chemical Industry: Fertilizer, salts, industrial sludge

Advantages Over Single-Drum Dryers

Lower fuel consumption(up to 30% energy savings)

Smaller footprint (suitable for modular setups)

Higher drying efficiency (reduced material sticking & clogging)

Longer service life (reinforced structure & corrosion protection)

New rotary dryer

Three-drum rotary dryer

Silica sand three-drum rotary dryer

1. High Thermal Efficiency

– Three concentric cylinders maximize heat exchange, reducing fuel consumption by 20-30% compared to single-drum dryers.

– Inner and outer drums optimize hot air circulation, minimizing heat loss.

2. Compact & Space-Saving

– The nested drum design reduces the machine’s length by 40-50%, making it ideal for limited-space installations.

3. Uniform Drying

– Material flows through multiple layers, ensuring even heat distribution and preventing over-drying or clumping.

4. Low Maintenance & Robust Construction

– Made from wear-resistant steel with thermal insulation to withstand high temperatures (up to 700°C).

– Reduced dust emissions with optional bag filters or cyclones.

5. Wide Material Adaptability

– Suitable for granular, powdery, and high-moisture materials (e.g., sand, coal, sawdust, ore, sludge).

Technical Specifications

– Capacity: 5–200 t/h (customizable)

– Moisture Reduction: From 30-40% to <1%(adjustable)

– Heat Source: Coal, gas, biomass, or electric heating

– Temperature Range: 150–700°C

– Control System: Manual or automated (PLC-based)

Construction: Sand, gravel, clay, gypsum

Mining & Metallurgy: Ore, mineral powder, slag

Agriculture: Biomass, wood chips, feed

Chemical Industry: Fertilizer, salts, industrial sludge