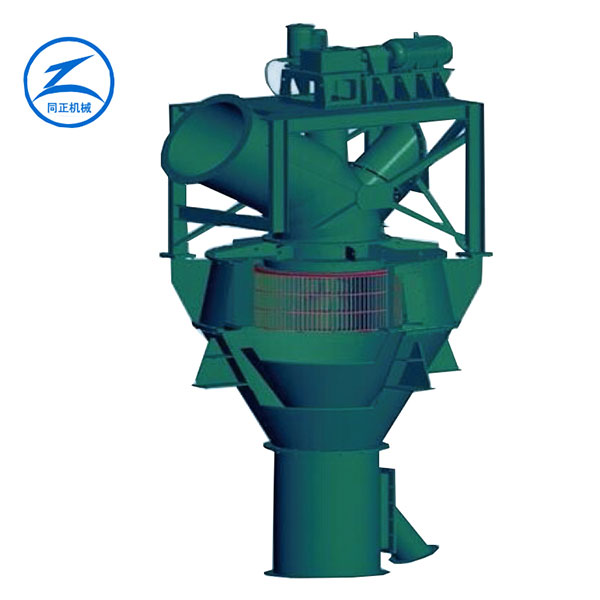

SEPAX high efficiency eddy current powder separator

SEPAX High-Efficiency Eddy Current Powder Classifier

Overview: The SEPAX High-Efficiency Eddy Current Powder Classifier offers the following outstanding advantages:

1. Its advanced classification principle combines multiple classification principles and utilizes aerodynamic analysis to optimize the entire flow field. The material undergoes two-stage classification, resulting in high and precise classification accuracy.

2. The classifier’s main shaft features stepless speed regulation. Fineness adjustment is convenient, sensitive, reliable, and has a wide adjustment range.

3. The classifier’s vulnerable wear parts, such as the spreader, cyclone horn, guide vanes, and rotor classifier vanes, are made of wear-resistant materials or treated with anti-wear technology, resulting in extremely low wear rates. The use of wear-resistant material as the inner lining effectively extends their service life.

4. The main shaft lower bearing seal utilizes a novel design, effectively addressing the two key issues of dust ingress and lubricant oil leakage, thereby significantly extending the service life of the lower bearing. 5. When designing the powder classifier foundation, the principle of mechanical vibration reduction is adopted to make the resonance frequency of the powder classifier and the foundation not close to the natural frequency of the powder classifier and the natural frequency of the foundation, which fundamentally solves the vibration problem of the powder classifier that has long troubled manufacturers.

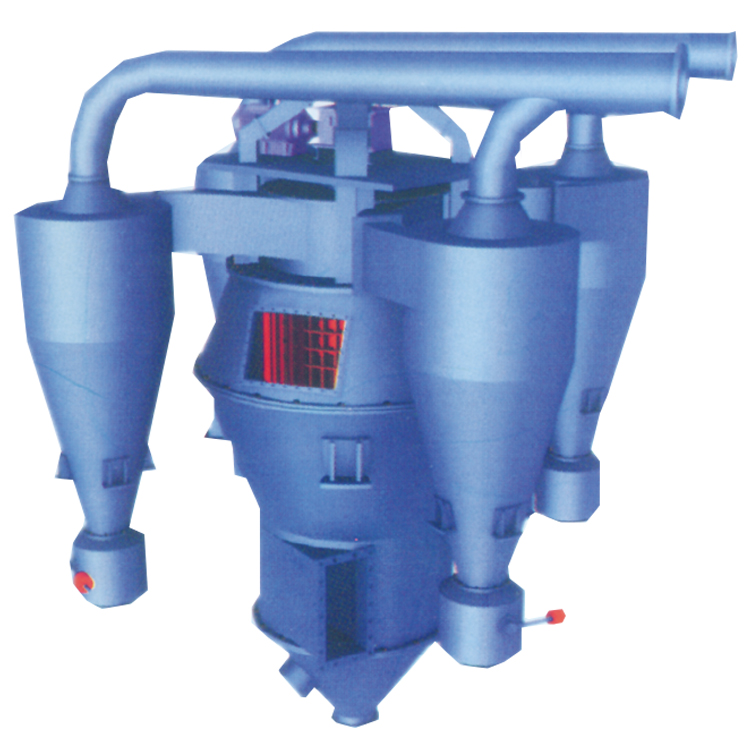

SEPAX high efficiency eddy current powder separator Description

Overview: The SEPAX high-efficiency eddy current classifier offers the following outstanding advantages:

1. Its advanced classification principle combines multiple classification principles and utilizes aerodynamic analysis to optimize the entire flow field. Material undergoes two-stage classification, resulting in high and precise classification accuracy.

2. The classifier’s main shaft features stepless speed regulation. Fineness adjustment is convenient, sensitive, reliable, and has a wide adjustment range.

3. The classifier’s vulnerable wear parts, such as the spreader, cyclone horn, guide vanes, and rotor classifier vanes, are manufactured from wear-resistant materials or treated with anti-wear technology, resulting in extremely low wear rates. The use of wear-resistant material lining effectively extends their service life.

4. The main shaft lower bearing seal utilizes a novel design, effectively addressing two key issues: dust ingress and lubricant oil leakage, thereby significantly extending the service life of the lower bearing. 5. When designing the powder classifier foundation, the principle of mechanical vibration reduction is adopted to make the resonance frequency of the powder classifier and the foundation not close to the natural frequency of the powder classifier and the natural frequency of the foundation, which fundamentally solves the vibration problem of the powder classifier that has long troubled manufacturers.

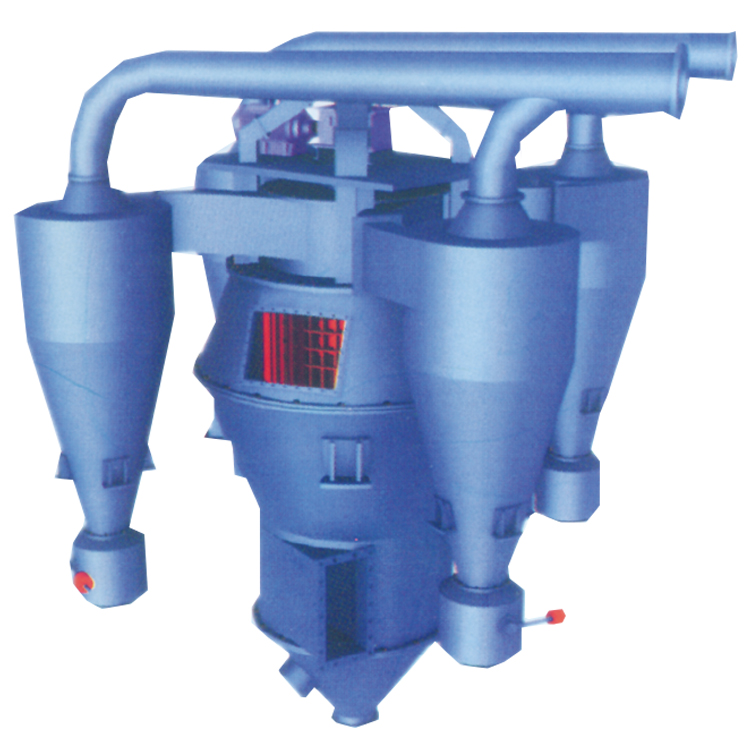

SEPAX high efficiency eddy current powder separator Technical Sheet

| item

model |

SEPAX-250 | SEPAX-350 | SEPAX-500 | SEPAX-750 | SEPAX-1000 | SEPAX-1250 | SEPAX-1500 | SEPAX-2000 | SEPAX-2500 | |

| spindle |

Motor model |

YCTL225-4B | YCTL250-4A | YCTL 250-4e | YCTL280-4A | Y200L-4 | Y225M-4 | Y225M-4 | Y250M-4 | Y280S-4 |

| power | 15 | 18.5 | 22 | 30 | 30 | 37 | 45 | 55 | 75 | |

| (rpm) | 150~400 | 150~350 | 150~320 | 140~320 | 130~280 | 130~260 | 120~240 | 110~200 | 110~180 | |

| Fan | Fan Model | 9-26 No10C | 9-26 No12.5C | 9-26No125d | SCF-12 No14C | SCF-12 No14B | SCF-12No16B | SCF-12 No168 | SCF-12 No18C| | SCF-12 No18B |

| (rpm) Speed | 1000 | 1080 | 1130 | 1100 | 1200 | 1050 | 1200 | 1050 | 1200 | |

| Total pressure | 5920 | 4921 | 4869 | 5764 | 5384 | 5582 | 5862 | 6272 | 5865 | |

| (m3h) Ar volume | 21465 | 30533 | 41021 | 46796 | 61280 | 76040 | 96631 | 120740 | 154910 | |

| Motor model | Y225M-4 | Y250M-4 | Y280S-4 | Y280M-4 | Y315M1-4 | Y315M2-4 | Y315M2-4 | Y355L1-4 | Y355M2-4 | |

| Power(kw) | 45 | 55 | 75 | 90 | 132 | 160 | 200 | 250 | 315 | |

| Capacity | P(45u) | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 | 0~3 |

| (m3/h) Air handling | 16000 | 22000 | 30000 | 45000 | 60000 | 75000 | 90000 | 120000 | 150000 | |

| (t/h)

Max processing capacity |

50 | 90 | 120 | 150 | 210 | 260 | 330 | 400 | 500 | |

| (t/h)

Production capacity |

10-18 |

15-28 |

20-40 |

30-50 |

40-70 |

50-85 | 75-110 | 95-130 | 110-160 | |