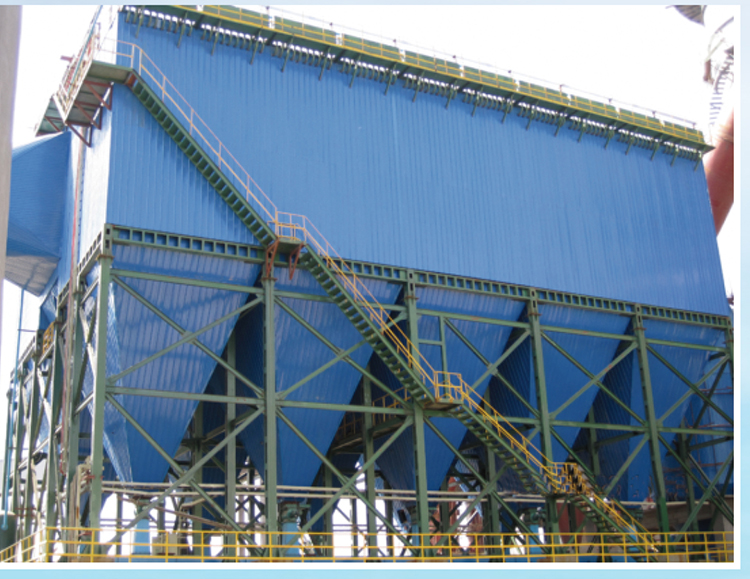

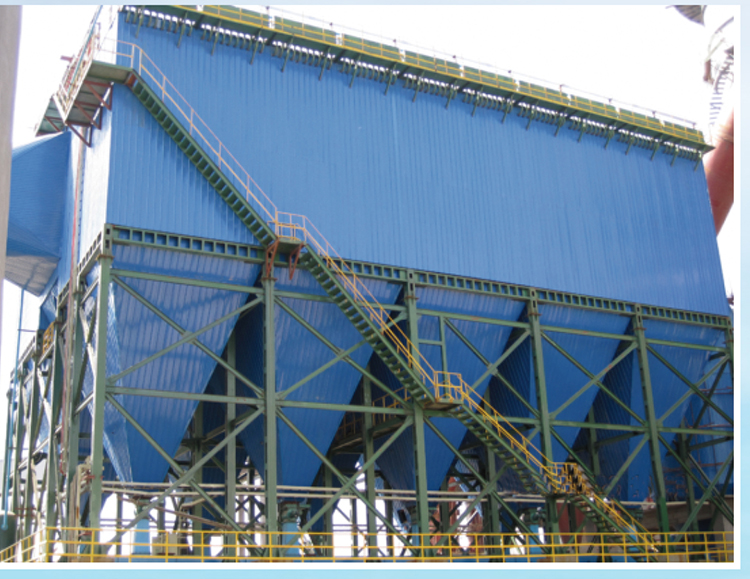

Explosion proof pulse bag dust collectors for coal grinding system

The coal mill explosion-proof pulse bag dust collectors is an efficient dust removal equipment specifically designed for coal powder preparation systems, with explosion-proof function, which can effectively handle coal powder dust and ensure production safety.

- Equipment Overview

-Purpose: Mainly used for collecting and purifying flammable and explosive dust generated by coal mills (coal powder preparation systems), commonly found in industries such as cement, electricity, metallurgy, etc.

-Core functions: Efficient filtration of coal powder dust (fine particle size), pulse cleaning, explosion-proof design.

- Working principle

-Filtering: The dusty gas enters the dust collector through the air inlet and is filtered through the surface of the anti-static filter bag. The dust is intercepted and the purified gas is discharged.

-Dust removal: Using compressed air pulse blowing technology, the accumulated dust on the filter bag is removed at a fixed time or pressure difference to maintain filtration efficiency.

-Explosion proof mechanism: Measures such as explosion-proof discs, explosion-proof valves, spark free design, and inert gas protection (such as CO ₂ or N ₂) are taken to prevent dust explosions.

- Core Structure and Characteristics

(1) Explosion proof design

-Explosion relief device: Install explosion relief discs or explosion-proof doors in the box to quickly release pressure during an explosion.

-Anti static filter bag: Made of conductive fiber material to prevent static electricity accumulation.

-Spark detection and fire extinguishing system (optional): Real time monitoring and extinguishing of fire sources.

-Explosion proof valve: prevents the spread of explosive flames to downstream equipment.

(2) Efficient filtration

-Filter bag material: Anti static polyester needle punched felt or laminated filter material is usually used, with a filtration efficiency of>99.9%.

-Pulse dust cleaning system: Automatic control of compressed air injection, thorough dust cleaning without damaging the filter bag.

- Advantages

-High safety: Multiple explosion-proof measures reduce the risk of explosion.

-Energy saving and environmental protection: Pulse cleaning has low gas consumption and meets emission standards.

-Automated operation: PLC control, real-time monitoring of parameters such as pressure difference and temperature.

-Long life design: The filter bag replacement cycle is long (usually 2-4 years).

Explosion-proof pulse jet bag dust collectors specifically designed for coal grinding systems Descriptions

The coal mill explosion-proof pulse dust collector is an efficient dust removal equipment specifically designed for coal powder preparation systems, with explosion-proof function, which can effectively handle coal powder dust and ensure production safety.

Explosion-proof pulse jet bag dust collectors specifically designed for coal grinding systems Technical/Data Sheet

| 技术参数 规格型号 Model | TZMB 96-4 | TZMB 96-5 | TZMB 96-6 | TZMB 96-7 | TZMB 96-8 | TZMB 96-9 | TZMB 96-10B | TZMB 96-12B | TZMB 96-14B | TZMB 96-16B | TZMB 96-18B | TZMB 96-20B | |

| 处理风量 Air volume(m2/n) | 22320 | 27900 | 33420 | 39000 | 44640 | 50160 | 55740 | 67260 | 78480 | 89640 | 100860 | 112080 | |

| 总过滤面积 Total filter area(m”) | 372 | 465 | 557 | 650 | 744 | 836 | 929 | 1121 | 1308 | 1494 | 1681 | 1868 | |

| 净过滤面积 Net filter area(m?) | 279 | 372 | 465 | 557 | 650 | 744 | 836 | 1028 | 1215 | 1308 | 1494 | 1681 | |

| 收尘室数(个) Chamber(pcs) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | |

| 每室袋数(条) Quantity of filter bag(pcs) | 96 | ||||||||||||

| 滤袋总数(条) Total quantity of filter bag(pcs) | 364 | 430 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1970 | |

| 脉冲阀(带电 磁闭) Pulse Valve | Quantity(pcs) 数量|个) | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 28 | 32 | 36 | 40 |

| 规格(英寸) Specification (inch) | 3″ | ||||||||||||

| 滤袋规格Specification of filter bag | 130*2450mm | ||||||||||||

| 滤袋材质 Filter material | 防水,防油,防静电绦纶针刺毡 Polyester needle-felt(water prcof,anti -oil and anti-static) | ||||||||||||

| 过滤风速 Filtration speed(m/min) | ≤1.0 | ||||||||||||

| 承受负压 Negative pressure(Pa) | 56000 | ||||||||||||

| 除尘器阻力 Resistance(Pa) | 1470~1770 | ||||||||||||

| 入口气体含尘浓度inlet dust concentration (g/Nm³) | <1000 | ||||||||||||

| 喷吹压力 Blowing pressure(Mpa) | 0.5~0.7 | ||||||||||||

| 压缩空气耗量Compressed air consumption (Nm³/min) | 2.4 | 3.0 | 3.6 | 4.2 | 4.B | 5.4 | 6.0 | 6.8 | 8.4 | 9.6 | 10.8 | 12.0 | |

| 锁风装置 Air-locking unit | 根据工艺情况需要确定 Adjustable | ||||||||||||

| 螺旋输送机 Screw conveyor | 根据工艺情况需要确定 Adjustable | ||||||||||||

| 保温面积 Area of heat preservation(m) | 132 | 144 | 156 | 168 | 180 | 192 | 210 | 240 | 270 | 300 | 330 | 360 | |

Explosion-proof pulse jet bag dust collectors specifically designed for coal grinding systems Applications

It is mainly used for the collection and purification of flammable and explosive dust generated in coal grinding (coal powder preparation systems), and is commonly found in the cement, power, and metallurgical industries.