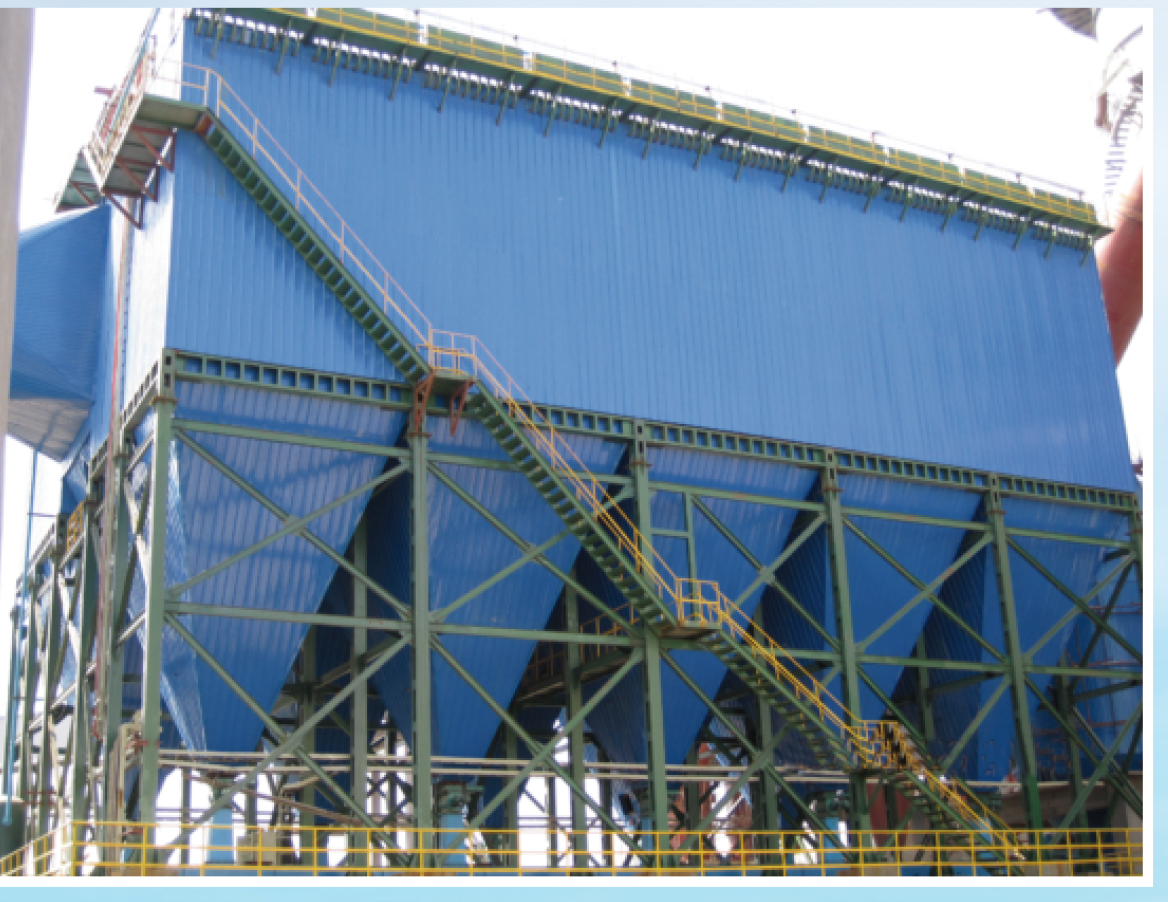

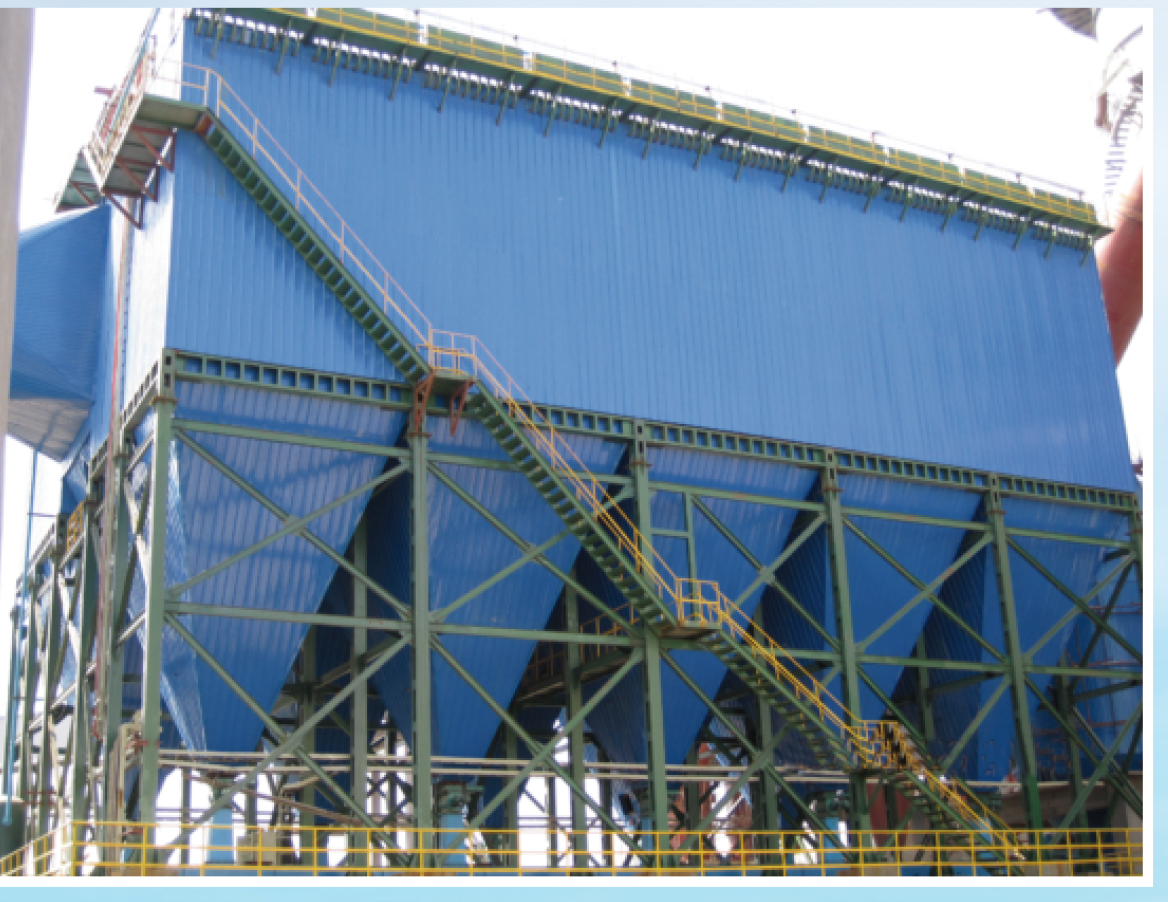

TZMC series large jet pulse long bag dust collector

TZMC series large jet pulse long bag type dust collector is a pulse long bag type dust collector developed by our company on the basis of jet pulse dust removal technology and in combination with advanced dust removal technology at home and abroad to meet the needs of large air volume flue gas purification

Performance characteristics

- The pulse jet ash cleaning technology is used, which has strong ash cleaning capacity, high dust removal efficiency, low emission concentration, small air leakage rate, less energy consumption, less floor area and stable operation and has good economic benefits. It is suitable for flue gas dedusting in metallurgy, building materials, machinery, chemical industry, electric power, light industry and other industries.

- The box is designed to be air tight with good sealing performance. The inspection door is made of excellent sealing materials. During the manufacturing process, diesel oil is used to detect and the air leakage rate is low.

- The outlet air duct is arranged compactly with small air flow resistance.

- The chamber air stop pulse jet is used to clean the ash, which has a long cleaning cycle and low consumption, and can double the service life of filter bags and valve pieces.

- The bag can be changed without stopping the machine, and the maintenance will not affect the normal operation of the equipment.

- The upper bag pulling method is adopted to improve the maintenance operation environment.

TZMC series large-scale jet pulse long-bag dust collector

TZMC series large jet pulse long bag type dust collector is a pulse long bag type dust collector developed by our company on the basis of jet pulse dust removal technology and in combination with advanced dust removal technology at home and abroad to meet the needs of large air volume flue gas purification. It combines the advantages of chambered reverse blowing dust collector and pulse dust-cleaning dust collector, overcomes the shortcomings of insufficient intensity of chambered reverse blowing dust removal and general pulse dust removal re-adsorption, so as to improve the dust removal efficiency and greatly reduce the injection frequency. The product uses submerged pulse valve, which reduces the pressure of injection air source and energy consumption of equipment operation, prolongs the service life of filter bag and pulse valve, and greatly improves the comprehensive technical performance.It is widely used in the purification of normal temperature or high temperature dusty gases in building materials, metallurgy, petrochemical, grain, steel, coal, power, garbage incineration, kiln and other industries and the recovery of powdered materials.

Performance characteristics

- The pulse jet ash cleaning technology is used, which has strong ash cleaning capacity, high dust removal efficiency, low emission concentration, small air leakage rate, less energy consumption, less floor area and stable operation and has good economic benefits. It is suitable for flue gas dedusting in metallurgy, building materials, machinery, chemical industry, electric power, light industry and other industries.

- The box is designed to be air tight with good sealing performance. The inspection door is made of excellent sealing materials. During the manufacturing process, diesel oil is used to detect and the air leakage rate is low.

- The outlet air duct is arranged compactly with small air flow resistance.

- The chamber air stop pulse jet is used to clean the ash, which has a long cleaning cycle and low consumption, and can double the service life of filter bags and valve pieces.

- The bag can be changed without stopping the machine, and the maintenance will not affect the normal operation of the equipment.

- The upper bag pulling method is adopted to improve the maintenance operation environment.

TZMC series large-scale jet pulse long-bag dust collector Technical/Data Sheet

| 规格型号 技术参数 model Technical Parameter | TZMC160 -2*5 | TZMC160 -2’6 | TZMC160 -2*7 | TZMC160 -2*8 | TZMC160 -2*9 | TZMC176 -2*5 | TZMC176 -2*6 | TZMC176 -2*7 | TZMC176 -2*8 | TZMC176 -2*9 | |

| 处理风量 Air volume(m³/h) | 23.04~ 28.8 | 27.65~ 34.56 | 032 | 46.88 | 5184 | 318 | 380 | 4.35 | 50 | 56 | |

| 总过滤面积 Total filter area(m²) | 4800 | 5760 | 6720 | 7680 | 8640 | 5305 | 6336 | 7392 | 8448 | 9504 | |

| 设备重量 G.Weight(T) | 138 | 165 | 193 | 220 | 248 | 150 | 180 | 210 | 240 | 270 | |

| 室数 Chamber(pcs) | 10 | 12 | 14 | 16 | 18 | 10 | 12 | 14 | 16 | 18 | |

| 滤袋 Filter bag | 数量(个) Quantity(pcs) | 1600 | 1920 | 2240 | 2560 | 2880 | 1760 | 2112 | 2464 | 2186 | 3168 |

| 规格(英寸) Specitication(inch) | Φ160*6000 | ||||||||||

| 脉冲阀 Pulse Valve | 数量(个) Quantity(pcs) | 100 | 120 | 140 | 160 | 180 | 110 | 132 | 154 | 176 | 198 |

| 阻力 Resistance(Pa) | ≤1500 | ||||||||||

| 过滤风速 Filtering wind speed(m/mi) | 0.8~1.0(如有用户需要,可根据具体情况降低或提高) If the user needs,according to particular case is lower or higher | ||||||||||

| 入口浓度 The entrance concentration(gNm²) | ≤100 | ||||||||||

| 漏风率 Air leakage rate(%) | ≤3 | ||||||||||

| 气源压力 Pressure(Mpa) | 0.3~0.5 | ||||||||||

| 技术参数 Technical Parameter 规格型号 model | TZMC192 -2*5 | TZMC192 -2’6 | TZMC192 -2*7 | TZMC192 -2*8 | TZMC192 -2*9 | TZMC208 -2*8 | TZMC208 -2*9 | TZMC208 -2*10 | TZMC208 -2*11 | TZMC208 -2*12 | |

| 处理风量 Air volume(m³/h) | 3456 | 33.17~ 41.47 | 3878 | 5.23 | 4272 | 459- | 53 | 9488 | 236 | 8985 | |

| 总过滤面和 Total fiter area(m²) | 5760 | 6912 | 8064 | 9216 | 10368 | 9984 | 11232 | 12480 | 13728 | 14976 | |

| 设备重量 G.Weight(T) | 154 | 185 | 216 | 245 | 276 | 262 | 295 | 325 | 358 | 390 | |

| 室数 Chamber(pcs) | 10 | 12 | 14 | 16 | 18 | 16 | 18 | 20 | 22 | 24 | |

| 滤袋 Filter bag | 数量(个) Quantity(pcs) | 1920 | 2304 | 2688 | 3072 | 3456 | 3328 | 3744 | 4160 | 4576 | 4992 |

| 规格(英寸) Specitication(inch) | φ160*6000 | ||||||||||

| 脉冲阀 Pulse Valve | 数量(个) Quantity(pcs) | 120 144 168 192 216 208 234 260 286 312 | |||||||||

| 阻力 Resistance(Pa) | ≤1500 | ||||||||||

| 过滤风速 Filtering wind speed(m/mi) | 0.8~1.0(如有用户需要,可根据具体情况降低或提高) If the user needs,according to particular case is lower or higher | ||||||||||

| 入口浓度 The entrance concentration(gNm²) | ≤100 | ||||||||||

| 漏风率 Air leakage rate(%) | ≤3 | ||||||||||

| 气源压力 Pressure(Mpa)

| 0.3~0.5

| ||||||||||

Note:1.The air volume is calculated in accordance with filtration speed of 0.8-1.0m/min and choose one based on the requirement of process.

- Choose filter materials based on the requirement of process.